Coating Material Photodefinable Polyimide PHOTONEECE™

PHOTONEECE™ is a liquid type photodefinable polyimide designed to accommodate various mechanical properties required by the makers of various semiconductor and electronic component makers around the globe. Product line-up consist of PW-Series (High temp. curable positive photodefinable), UR-Series (High temp. curable negative photodefinable), LT-Series (Low temp. curable positive photodefinable) and PN-Series (Low temp. curable negative photodefinable). These products are utilized for passivation and dielectric layers necessary for devices and components.

Features

- High reliability (high heat resistance, mechanical properties, dielectric constant and chemical resistance)

- Excellent photo sensitivity and patterning dimensional control

- Variety of product line-ups for maximum process versatility

Applications/Usage

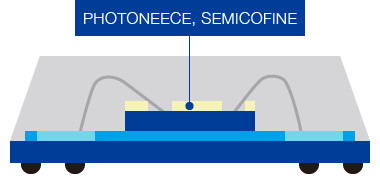

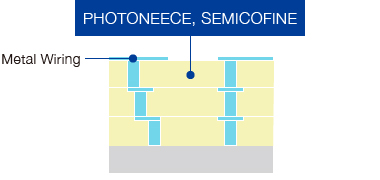

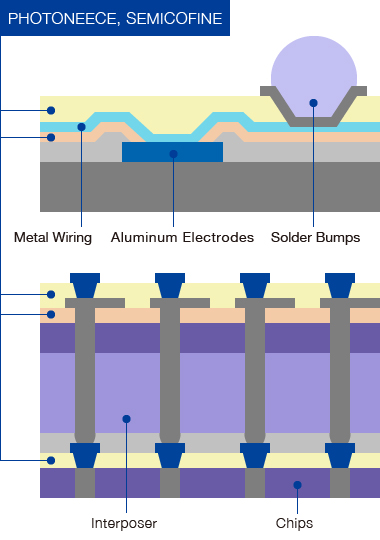

- Buffer coating / Passivation for IC Chips

- Dielectric layers for RDL (WLP and PLP)

- Dielectric layers and cavity / MEMS formation for electronic components.

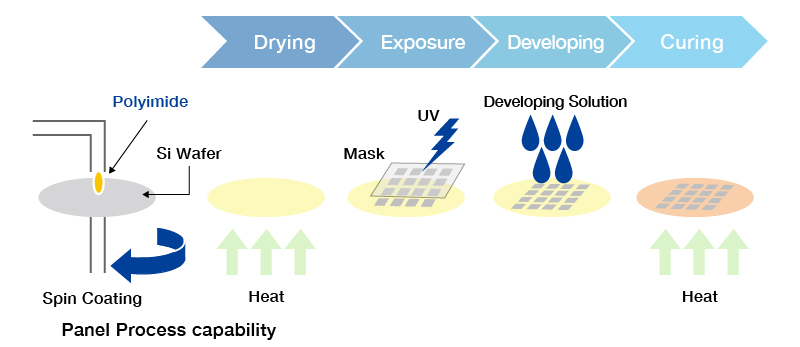

PHOTONEECE Process Example

Application Examples

Standard Products

◆Basic Properties

| GN Series | LT Series | PW Series | |

|---|---|---|---|

| Features | Thick film applicable, High thermal resistance |

Low temperature curable, High resolution |

High sensitivity, High resolution |

| Type | Negative tone | Positive tone | Positive tone |

| Developer | Alkali | Alkali | Alkali |

| Cure temperature(℃) | ≧300 | ≧200 | ≧300 |

| Film thickness(μm) | 8~20 | 1~11 | 1~11 |

| Resolution(μm) | ≧30 | ≧5 | ≧5 |

◆Material Property Data

| GN Series | LT Series | PW Series | |

|---|---|---|---|

| Tensile strength(MPa) | ≧150 | ≧130 | ≧150 |

| Elongation(%) | ≧40 | ≧50 | ≧50 |

| Modulus(GPa) | ≧3 | ≧2 | ≧3 |

| CTE(ppm/℃) | ≦50 | ≦50 | ≦40 |

| Glass transition temperature(℃) | ≧300 | ≧270 | ≧300 |

| 5% weight reduction temperature(℃) | ≧500 | ≧350 | ≧450 |

Fluorine-free Products

◆ Basic Properties

| GN-K Series | LT-K Series | PW-K Series | |

|---|---|---|---|

| Features | Low temperature curable, Thick film applicable |

Low temperature curable, High resolution |

High sensitivity, High resolution |

| Fluorine free, NMP free | 〇 | 〇 | 〇 |

| Type | Negative tone | Positive tone | Positive tone |

| Developer | Alkali | Alkali | Alkali |

| Cure temperature(℃) | ≧200 | ≧200 | ≧300 |